What Are Nickel Electroplating Services and Why Are They Important?

Discover how nickel electroplating enhances part durability, corrosion resistance, and performance across industries. Learn its benefits and key uses.

When it comes to extending the life of metal parts and improving their performance, nickel electroplating plays a pivotal role. This process adds a protective layer of nickel to the surface of a component, enhancing everything from corrosion resistance to surface hardness. Whether its automotive, aerospace, electronics, or industrial machinery, nickel electroplating quietly powers much of the reliability we expect from modern metal products.

What Is Nickel Electroplating?

At its simplest, nickel electroplating is a surface treatment process. It uses electric current to deposit a thin, even layer of nickel onto a metal object. The item is submerged in a bath containing a nickel salt solution, and when current flows through, nickel ions bond to the part's surface. This coating acts as both a shield and a finish, protecting the material beneath while offering a smooth, durable outer layer.

Why Is It So Widely Used?

Fights Off Corrosion:

Nickels natural resistance to moisture, air, and many harsh chemicals makes it a great shield for metal parts. When components are exposed to tough environments, think marine equipment or industrial machinery, a nickel coating service acts like armour, helping them stay rust-free and reliable for years.

Handles Wear and Tear:

If a metal part moves, slides, or takes regular impact, its going to wear down fast. Thats where nickel comes in. A well-applied coating gives softer base metals a tougher exterior, reducing wear from friction and helping parts last much longer in daily use.

Supports Electrical Precision:

In the electronics world, every micron counts. A smooth, even layer of nickel ensures steady conductivity, making it a go-to choice for electrical connectors, terminals, and sensor contacts. It not only maintains flow but also avoids performance glitches caused by uneven surfaces or oxidation.

Clean Looks With Purpose:

Theres a reason nickel is often used for both performance and presentation. That shiny, silver finish doesnt just look sharp; it resists damage, extends the components usable life, and adds a layer of refinement that matters in both industrial and consumer products.

Common Applications

-

Automotive components like fuel system parts, pistons, or transmission gearboxes.

-

Electronics, including connectors, printed circuit boards, and battery contacts.

-

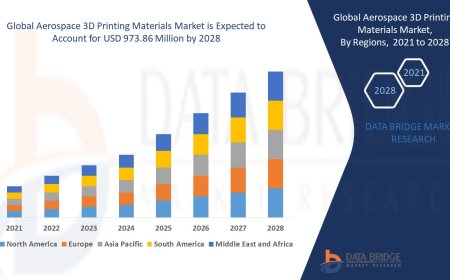

Aerospace parts require high precision, heat resistance, and strength, which are non-negotiable.

-

Industrial machinery, especially components that face frequent exposure to moisture, pressure, or chemicals.

Final Thoughts

Nickel electroplating is more than a surface-level upgrade. Its a smart move for anyone who values performance and long-term durability. Its not just about making a part look good; its about helping it last, even in tough conditions where rust, wear, or pressure would normally take a toll.

Whether youre working with high-precision electronics or rugged industrial machinery, a well-executed nickel coating gives your components the strength and resilience to keep performing not just today, but for the long haul.